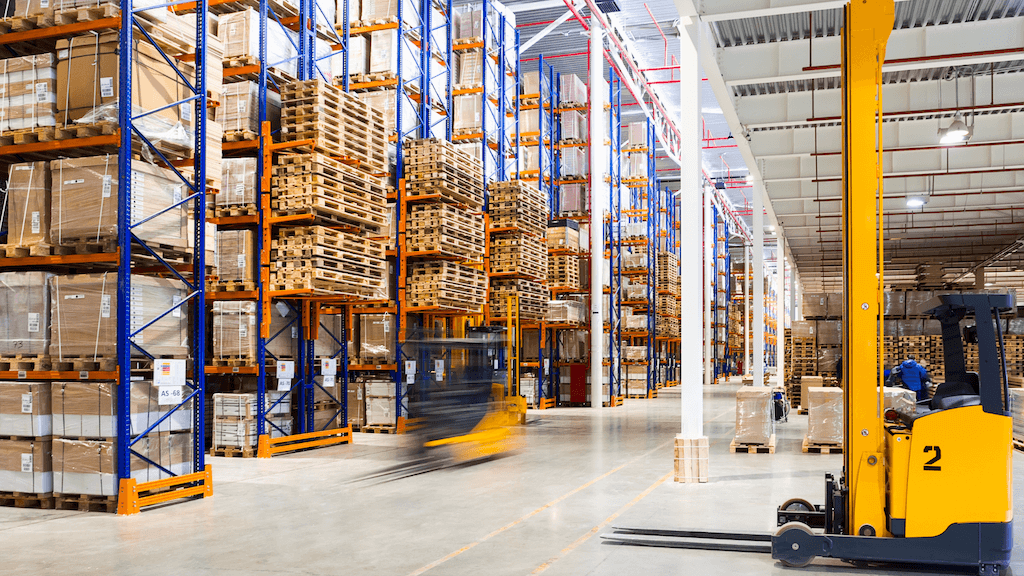

MaxinAI’s solution helps warehouses in product allocation and space optimization, requiring the lowest costs and producing the highest efficiency.

Goal

Our client, a California-based company that provides consulting services to warehouses wanted to give its customers recommendations on warehouse logistics that would lower costs and increase productivity and efficiency.

When we think of a warehouse, we think of simple operations such as moving goods from one place to another. However, warehouse managers know the real struggle associated with efficient space management.

Inefficient space management can lead to excessive travel distances for employees, stock-outs and lost sales, and longer fulfillment times. That’s why effective space allocation and inventory management are some of the most challenging tasks that managers still tackle with difficulty.

Some of the difficulties related to warehouse management include:

- Poor space/layout management practices

Problems such as not knowing the exact capacity of the space or not being able to correctly analyze the specificity of the design can be detrimental to the warehouse and hinder the growth of a company.

- Excess stock

When the company does not sell the goods in a timely manner or when there is more product than the demand, the goods tend to accumulate and become an expense for the company and are associated with lost revenue due to additional capital tied to occupied storage space.

- Product misallocation

Placing the best-selling goods in the back while the least-selling ones are in the front or unnecessary product handling becomes an additional and unnecessary operation that can add considerable cost to a business. Even a small optimization in this operation produces significant results in terms of reducing costs and maximizing efficiency.

- Lack of human capital

Due to the lack of information on warehouse operations, sometimes the human resources employed are not enough, causing process delays and slowing down warehouse efficiency.

One solution to rule them all

The challenges mentioned above can be difficult to tackle at times and the consequences are often damaging. But what if we told you that there may be a single solution that not only solves all the problems mentioned above, but also improves the overall performance of the warehouse?

As smart AI solutions have penetrated almost every sector, logistics is no exception. Innovative tools are constantly being introduced to help managers better handle the warehouse and its activities.

The truth is that warehouses already have the necessary data that is useful for the optimization of processes and, in addition, their improvement. However, what they lack are the tools that can make sense of all this data and give concrete suggestions for improvement.

Exactly based on the data, we provided a program that uses optimization methods and obtains information about the warehouse installation (space allocation, product dimensions), sales history, customer order behavior, etc.

Subsequently, it recognizes patterns and regularities from the aforementioned information which is then used to inform decisions and give suggestions on how to improve warehouse operations, such as product allocation and space optimization that requires the lowest cost and provides the highest efficiency.

Now, thanks to our solution, managers have access to suggestions such as shorter walking routes for better timely service or better inventory positioning based on product popularity. So for example, based on years of sales data of different products, our smart solution ranks product popularity and recommends the end-user to place the highest ranked product in front of the warehouse so less time and energy are wasted in loading and moving the product.

Transforming warehouse management

The implementation of AI and intelligent solutions in warehouse management has become even more important in today’s environment when customer satisfaction and competitive advantage have become core factors for the success of the company.

Warehouse management acts as a bridge between the supplier and the customer; therefore, streamlined warehouse operations mean improved supply chain management and happier customers.

Do you have a project in mind? You could be our next success story! Get in touch with our experts to discuss your project potential and get a free pilot project from us.